Winter seminar series to look at EU Fashion Policy & Legislation: Compliance Strategies for the Future

Fashion's future is tightly intertwined with policy and legislation, especially in the EU, one of the world's largest fashion markets.

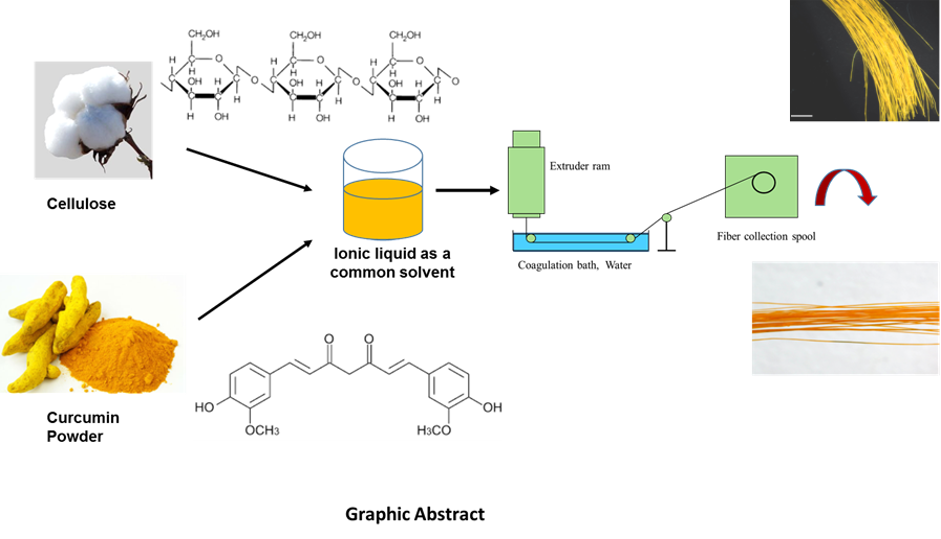

Eco-Textiles - Regenerated Cellulose Fibres Manufacturing using an Environmentally Benign Process

According to the World Bank, 20% of land and water pollution globally is caused by textile processing industries. Regenerated cellulose fibres manufacturing processes, like those used to create Viscose/Rayon, use renewable wood pulp cellulose. However, this fibre spinning process uses highly aggressive chemicals, like carbon di-sulphide, sulphuric acid and sodium hydroxide, which leaves a large environmental footprint.

As a part of our research at Cranfield University, we developed a regenerated cellulose fibre manufacturing process using environmentally benign solvents and natural dyes. Regenerated cellulose fibres will help reduce pollution from the Rayon fibres manufacturing process, while the use of natural dyes will reduce the environmental impact from using toxic synthetic textiles dyes. The regenerated cellulose fibres and use of natural dyes developed in our lab can potentially help address the demand for sustainable fashion products. The fifth session will focus on Materials Circularity and will be led by Dr Sameer Rahatekar from Cranfield University.

This event was held on Tuesday, 26 April 2022.

Fashion's future is tightly intertwined with policy and legislation, especially in the EU, one of the world's largest fashion markets.

Join the TCC in an exciting event featuring external speaker Lisa Lang, an expert in policy and legislation. Discover how the arts and culture sector can address climate change and navigate the evolving EU regulations.

Join us for an hour-long seminar to show the outcomes of the British Academy of Medical Sciences Global Challenges Research Fund (GCRF) project entitled ‘A Brazil-UK Network for Natural Polymers derived from Local Food Industry By-products’ with our international partners from Universidade de São Paulo in Brazil.